Festo Components Ensure Top Performance of Robotic Palletizing System

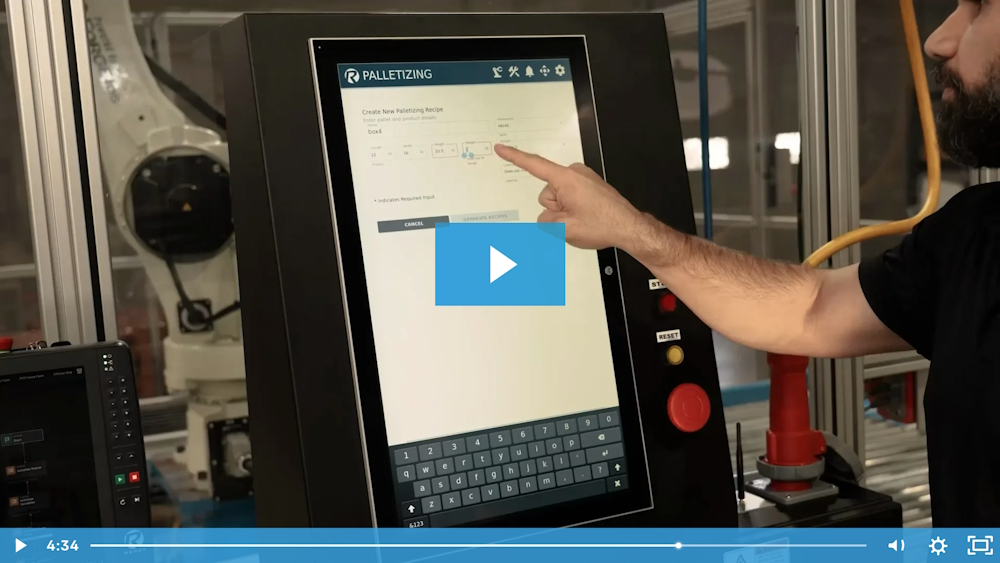

READY Robotics, Columbus, Ohio, applied advanced software engineering to develop READY Cells: Palletizing, a customizable palletizing cell now available through Rockwell distributors. READY Cells: Palletizing re-envisions specifying, operating, and maintaining palletizing cells in terms of ease of use, flexibility, and output. In this short video, Allan Gibson, READY Robotics Vice President of Manufacturing Technology & Automation, describes Rockwell Automation’s investment in READY Robotics, READY Cells: Palletizing innovations, and why Festo technology is in every palletizer.

READY Robotics selected Festo components to ensure top performance. These components include the MSB6 air preparation system with SV soft start/quick exhaust safety valve. The VTUG valve bank, controlled via IO-Link, simplifies installation. Festo DFM guided pneumatic cylinders are used for pop-up stops and pushers to center pallets before the palletizing process begins. The IO-Link enabled SDAT dual-position proximity sensor requires only a single point on an IO-Link Master module. This is a benefit since it gives designers greater flexibility in the choice of other IO-Link components.