White Papers

An Overview of Functional Safety in the Process Industry

Implementing functional safety is critical in the process industries, which include dangerous chemical, petroleum and petrochemical applications. The systems in these industries, down to the lowest practical level, must be designed to reduce hazards against people, property and the environment—especially in the event of a malfunction or failure.

Download The White PaperFive steps to making efficient, error-free process adjustments

Modern automation systems increasingly need to adapt to various products in multiple sizes and configurations. And one result of this variability is having to make frequent process adjustments to flow, pressure, end-stop limits and machine speed, to name a few. All too often, however, this ongoing need to make process adjustments opens itself up to unwanted device tampering, which can easily cause a machine or process to spiral out of control.

Download The White PaperConnecting the Factories of Tomorrow—Today

With the rise of the Industrial Internet of Things (IIoT), production systems are driving toward a “seamlessly connected” future, in which all mechanical, electrical and intelligent interfaces work together as one complete package—including the motors, drives, controllers and Cloud. Although we’re not there yet, this future holds exceptional promise for the factories of tomorrow in terms of higher productivity rates, better product quality and lower costs.

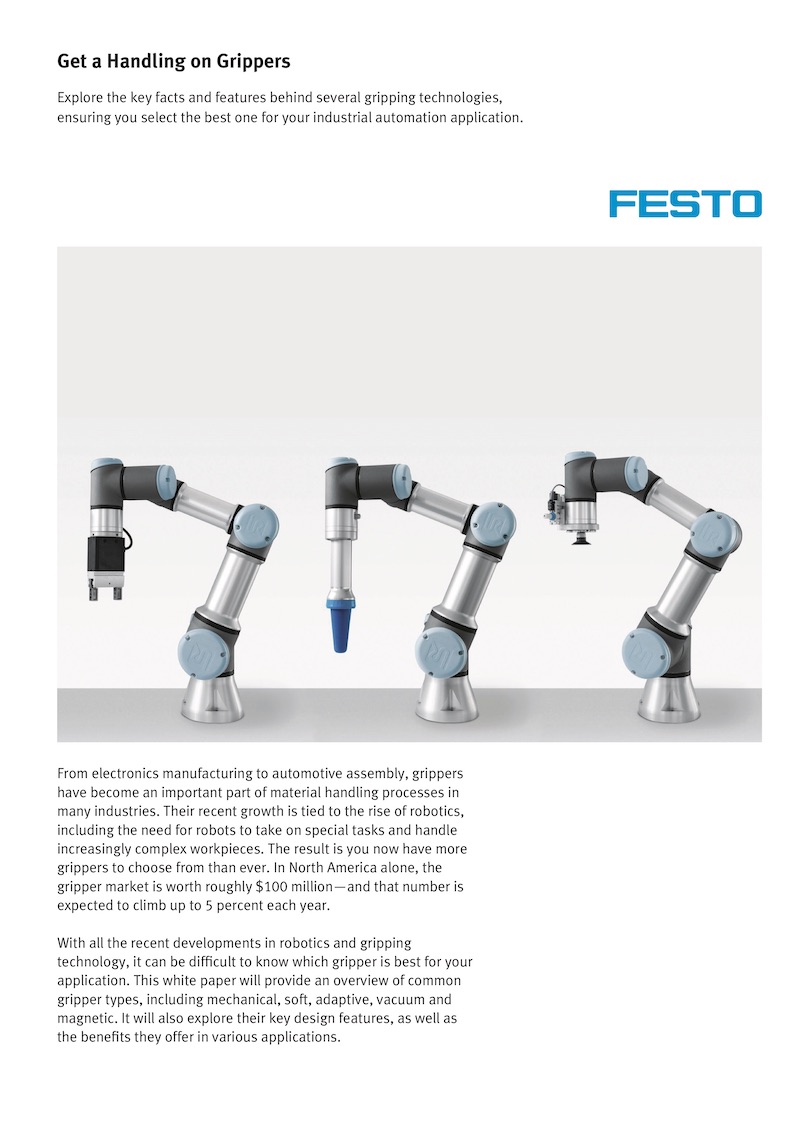

Download The White PaperGet a Handling on Grippers

Explore the key facts and features behind several gripping technologies, ensuring you select the best one for your industrial automation application.

Download The White PaperOverall Equipment Effectiveness

Maximum availability is not something that happens by chance, it’s the result of forward-looking action. Processing food economically and at the right time is absolutely essential. Otherwise there is a risk that production has to be stopped and raw materials are wasted. Taking overall equipment effectiveness into consideration provides clear guidance on how to maximise productivity, and thus on economic operation of the system.

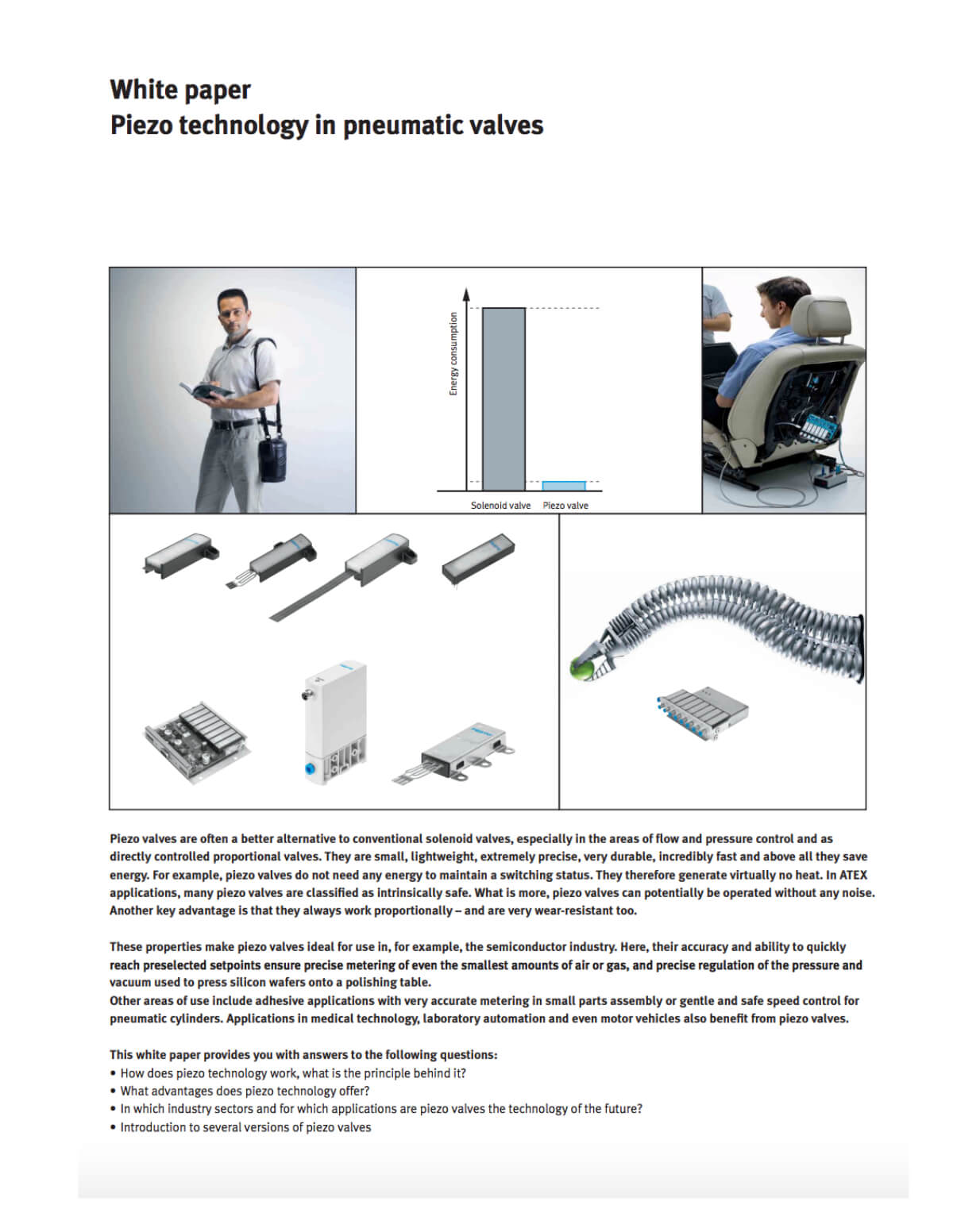

Download The White PaperPiezo Technology

Piezo valves are often a better alternative to conventional solenoid valves, especially in the areas of flow and pressure control and as directly controlled proportional valves. They are small, lightweight, extremely precise, very durable, incredibly fast and above all they save energy. For example, piezo valves do not need any energy to maintain a switching status. They therefore generate virtually no heat. In ATEX applications, many piezo valves are classified as intrinsically safe.

Download The White PaperAir Cushion Solution

A common goal throughout the business world is to increase productivity while reducing costs. This certainly applies to machine design, which means achieving the fastest possible cycle times. For pneumatic systems, this often requires running actuators as fast as possible without introducing excessive shock loads to the system.

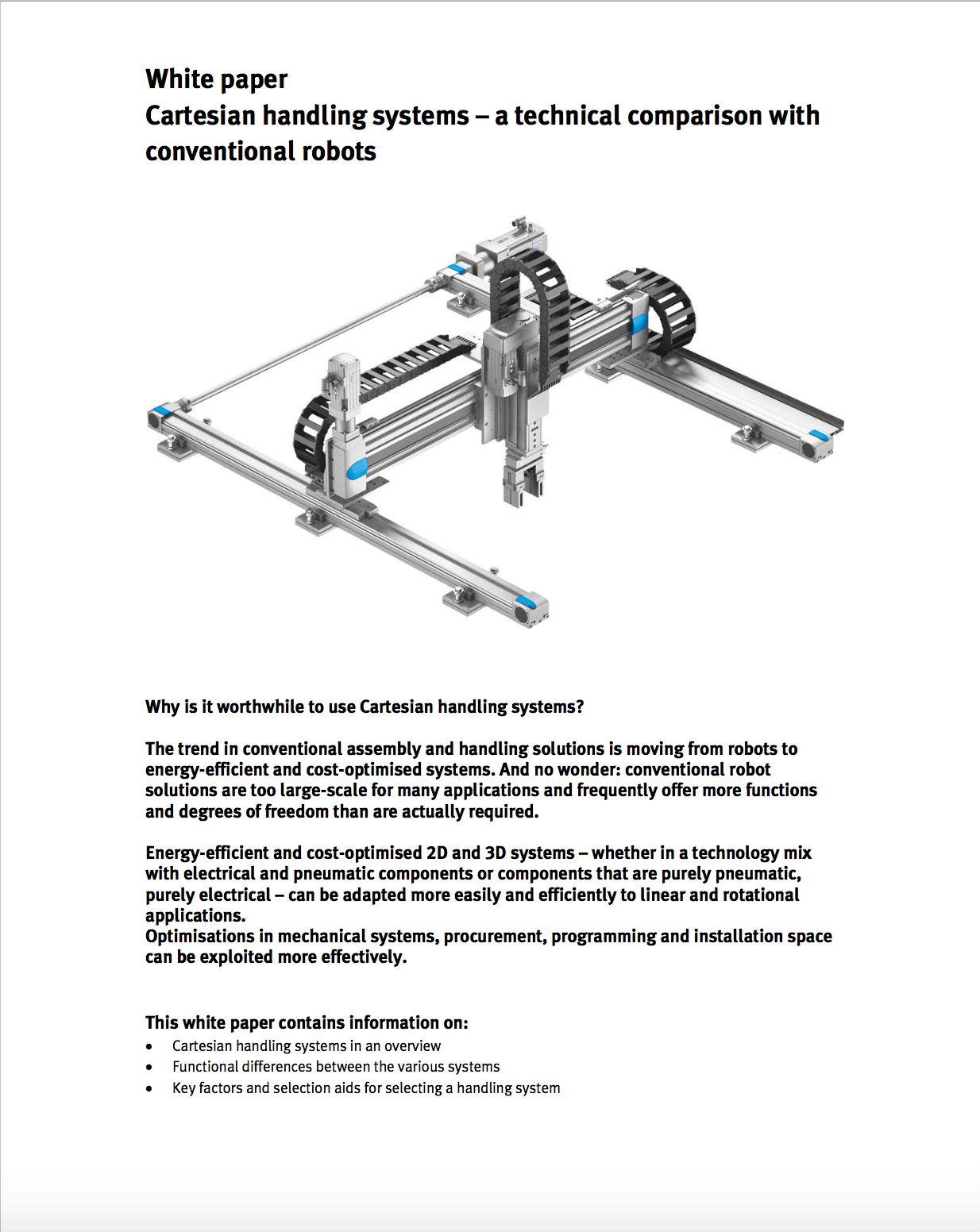

Download The White PaperCartesian Handling Systems

The trend in conventional assembly and handling solutions is moving from robots to energy-efficient and cost-optimised systems. And no wonder: conventional robot solutions are too large-scale for many applications and frequently offer more functions and degrees of freedom than are actually required.

Download The White PaperDigital Simplicity

The so-called “smart” cyber-physical systems (CPS) are completely new. They are set to increase production and make it much more flexible. And they are set to change traditional processes in the value chain by simplifying them – this is what is called digital simplicity. They are leading to autonomous production with selfregulating systems.

Download The White Paper