Life Science Initiatives at Festo — From Dispensing Systems to Lab-on-a-Chip Design

The role of automation in advancing life science applications cannot be overstated. At Festo, we support systems and equipment manufacturers with cutting-edge components and systems that are taking medical technology and laboratory automation to new heights. Check out some of our recent initiatives in this sector.

Automated Cell Dispensing Systems

Whether to develop new drugs or test alternative forms of therapy, working with cell cultures is critical in many life science applications. However, manual pipetting takes time, is prone to human error and ties up skilled personnel, necessitating the need for automated dispensing systems that offer greater speed and efficiency.

At Festo, we offer many components that support the design of modular and flexible dispensing systems that use compressed air for handling cell suspensions in a gentle yet precise way. You can even adapt the pressure of these systems according to cell line and concentration. As a testament to the effectiveness of these systems, we tested their impact on cell viability and found that the average cell viability was similar to that of the manually pipetted samples.

These results point to the ability of automated dispensing systems to handle cell cultures with the gentleness of manual pipetting — while offering the benefits of automation.

Learn more: Automated cell and organoid dispensing | Festo USA

Design for Manufacturing of Lab-on-a-Chip Devices

Scientists, universities, startups and manufacturers are reducing the time to market for their lab-on-a-chip systems using Festo components. These benefits are made possible through collaborative engineering and the use of modular, ready-to-install subsystems.

Our miniature components include valves for controlling closely packed channels, sensors for monitoring the pressure or position of the lab-on-a-chip device — and more. We also design valve blocks based on your microfluidic chip layout and select the modules that best meet your specifications.

By using pneumatic components when possible, our designs offer reliable operation with minimal heat generation, eliminating the need for additional cooling components. Built-in pressure and vacuum generation also means no external air supply is necessary.

Learn more: Design for Manufacturing of lab-on-a-chip devices | Festo USA

Unlocking the Benefits of Pressure-Controlled Liquid Handling Systems

While there are many different types of systems for handling liquids in lab automation, we favor pressure-controlled dosing systems because they offer a wide range of benefits. You can easily scale and combine our products to design your own system and unlock the benefits for yourself. These advantages include:

- Simplicity. These systems are mechanically simple and require a small number of components, minimizing the number of moving parts and facilitating cleaning.

- Precision. Dispense even 1-microliter volumes precisely and reliably with a coefficient of variation of <1% — depending on the liquid volume and ambient conditions.

- Flexibility. Change and adjust parameters to precisely dispense a wide range of liquids. You can also adapt the systems according to specific needs.

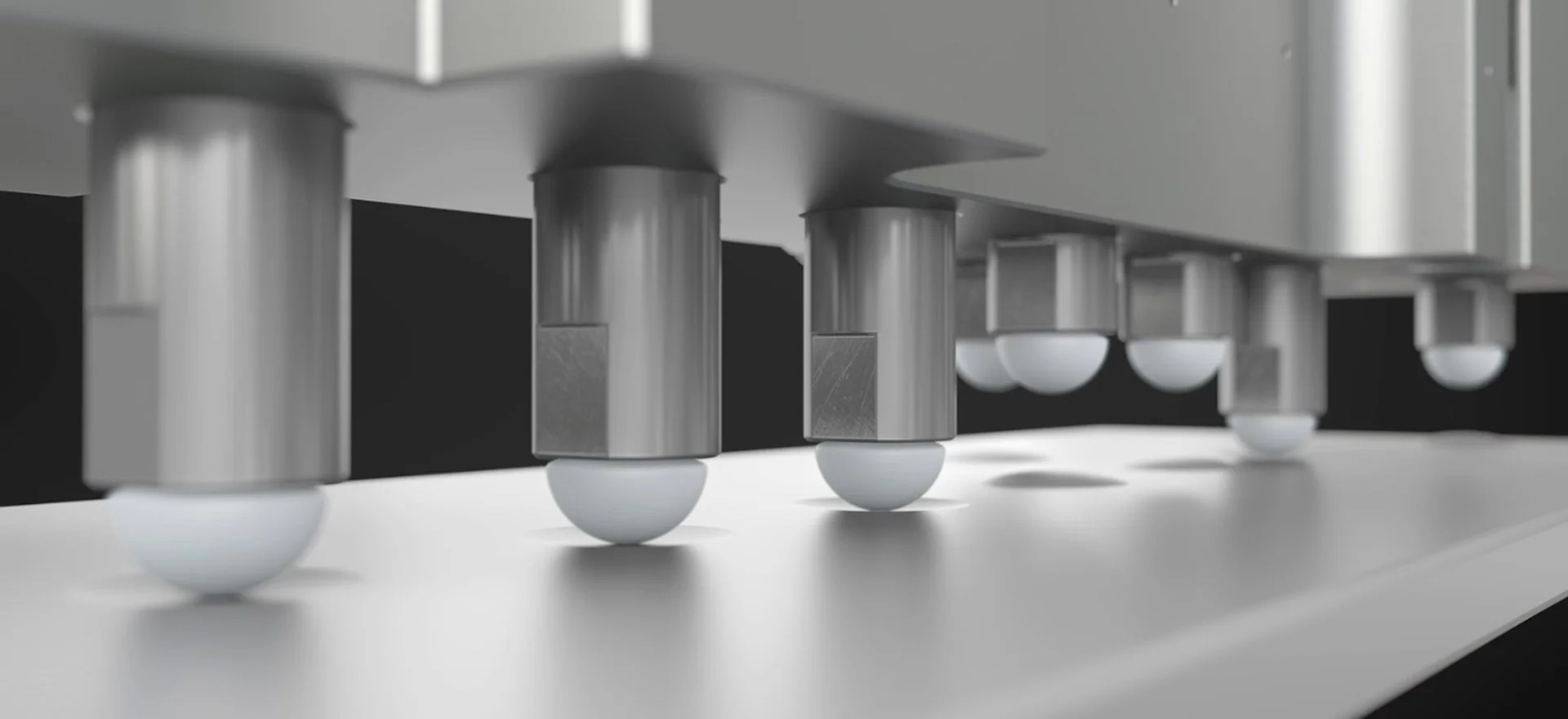

- Scalability. Combine individual dispense heads by mounting them on a rail with a freely selectable grid. You can also control the heads independently to dose different liquids simultaneously.

- Productivity. Pressure-controlled dosing systems offer high flow rates and constant flow pressures, optimizing performance compared to other systems. You can also easily integrate dispense heads into a planar surface gantry, increasing throughput.

Learn more: Five benefits of pressure-controlled liquid handling | Festo USA