Digital Pneumatics: A Step Toward Universal Gripping

The universal gripper, the holy grail of robotics, is a one-size-fits-all component that can pick up anything, from a toothpick to a 20-pound case. Moving us in this direction is the advancement of digital pneumatic technology, which operates at the intersection of traditional pneumatics and electric automation.

The development of universal grippers, based on digital pneumatics, is driven by industries like ecommerce — which requires robots to handle various materials and items, for example — as well as robotic operations for singulating and packing goods like bubble wrap, tubes, polythene (poly) bags, corrugated packages, envelopes and more.

A Universal Foam Gripper Cup

At the forefront of these developments, Festo offers a universal foam gripper cup featuring a foam ring interface. Used in singulation applications, this gripper is ideal for apparel poly bags and other soft materials that can challenge traditional vacuum cups or mechanical grippers. These grippers also work well in agricultural applications — picking fruit off the vine, for example.

The special foam-lipped gripper has a lightweight yet rigid polymer body that provides high stiffness during lateral movements with heavy objects. This foam lip is a low-cost sealing surface that can form a vacuum seal on a wide range of product surfaces, textures and shapes. Thanks to the vacuum’s simple operating principle, this gripper is a big step in the direction of universal gripping without sacrificing weight or speed.

Additional Advancements in Gripping Technology

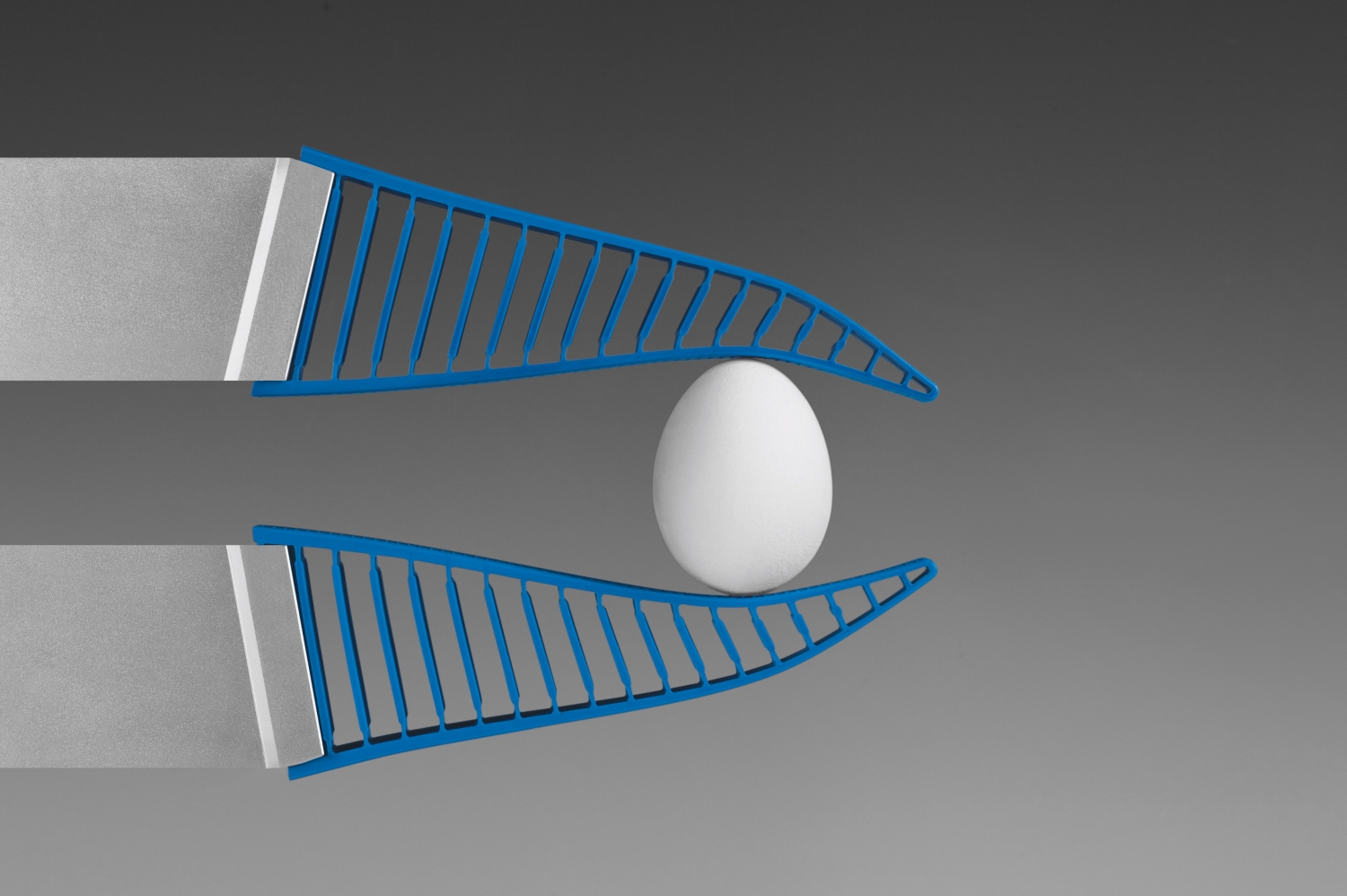

Many recent gripper innovations move away from traditional mechanical jaws and vacuum cups, instead incorporating soft designs that adapt to a part’s unique shape and material. In many cases, these adaptive grippers are based on designs in the animal kingdom:

– The first example is based on a fish tail fin, which, if pressed, curves around the pressure point instead of bending.

– A second example is based on a chameleon’s tongue. This bionic gripper, called the FlexShapeGripper, consists of a double-acting cylinder, with one chamber filled with compressed air and the other filled with water.

– A third example is a self- contouring “finger gripper” that utilizes the same technology as the BionicSoftHand. This component, which supports digital pneumatics, incorporates proportional piezo valves that precisely control the fingers.

To learn more about the latest advancements in gripper technology, check out our e-book.