How to Reduce Manufacturing Downtime and Costs

Unplanned downtime costs manufacturers millions in lost production, inflated labor costs and product waste. The good news? It’s largely preventable. By shifting from reactive to predictive maintenance strategies, you can dramatically reduce unexpected shutdowns and boost plant efficiency.

To help you get started, our automation experts share strategies for improving operations and cutting costs. Here’s a rundown of the key topics they discuss.

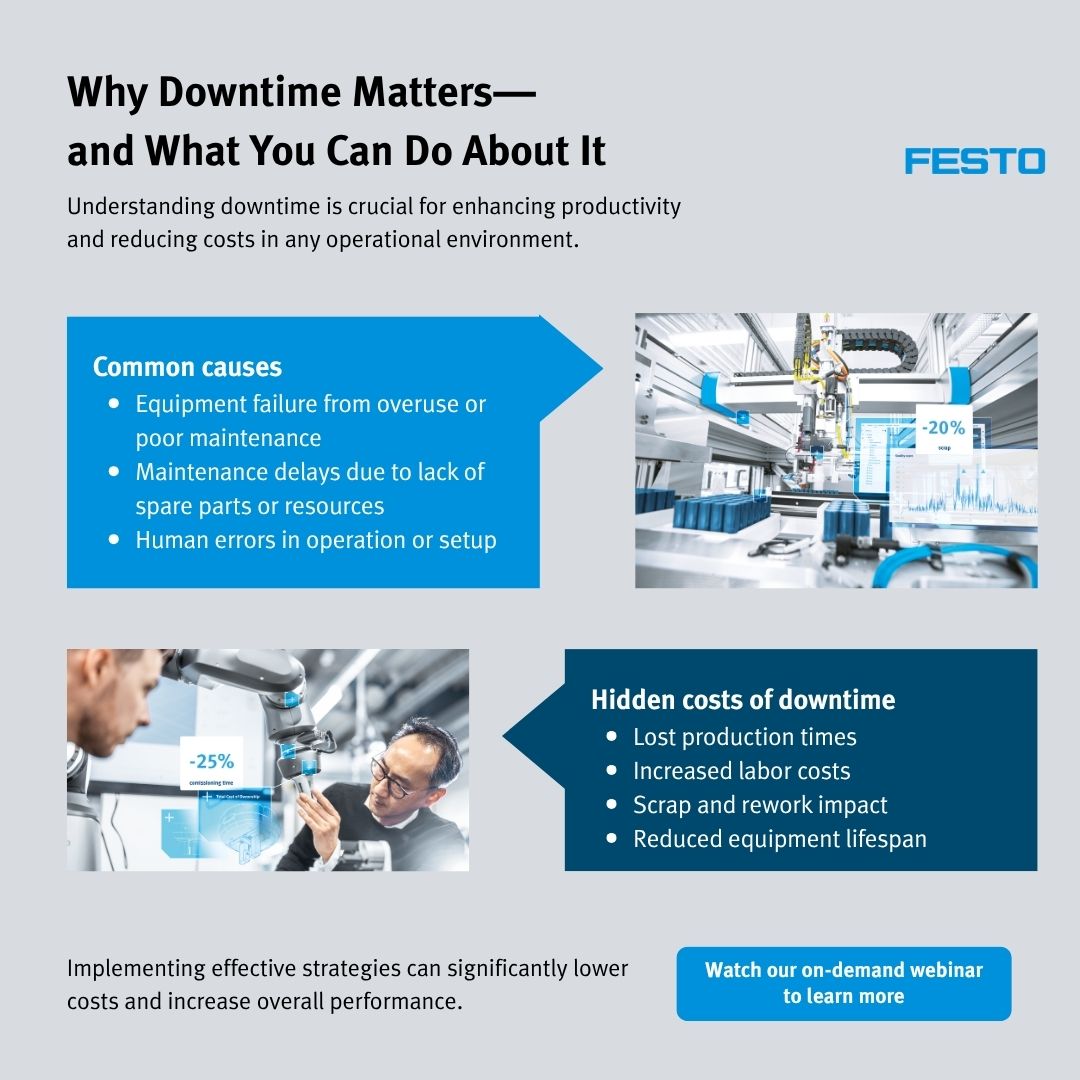

The Hidden Costs of Downtime

Unplanned downtime can stem from equipment failure, spare parts shortages or human error. But the costs extend far beyond the initial breakdown. For example, tubing that is improperly seated into a pneumatic fitting can cause an air leak, forcing the compressor to run harder and longer than necessary, driving energy costs and reducing system efficiency. Meanwhile, if that leaky actuator doesn’t extend as quickly as it should during its cycle, it might fail to complete its task properly, producing defective products before anyone notices the problem. The result — additional costs through scrap, rework or production restarts.

Making the Shift to Predictive Maintenance

The solution lies in anticipating problems before they become emergencies. Here are some ways to shift toward a more predictive approach:

- Implement IoT sensors: Real-time data from embedded sensors, electronic pressure regulators and digital devices provides instant visibility into machine performance./li>

- Analyze trends and detect anomalies: Software establishes machine baselines and flags deviations, giving you early warnings before failures occur.

- Use dashboards for visibility: Integrated data displays let you monitor operations remotely and diagnose issues faster, reducing the duration of shutdowns.

How Electric Automation Can Help

Electric automation and motion control systems offer significant advantages over traditional pneumatic systems, enabling you to further reduce downtime in the following ways:

- Precise control: Unlike abrupt pneumatic movements, electromechanical systems provide exact control over speed, acceleration and position, reducing errors.

- Extended lifespan: Controlled acceleration/deceleration minimizes mechanical stress, prolonging equipment life.

- Real-time diagnostics: Servo drives and motors continuously monitor torque, amperage and position, detecting potential failures before they occur.

The ROI Reality

While electric automation requires higher upfront investment, pneumatic systems quickly lose value when leaks develop, driving your energy costs. The long-term benefits of electric automation — such as increased flexibility, higher-quality output and dramatically less downtime — deliver substantial ROI that far exceeds the initial investment.

To get started making the switch, consider an incremental approach. For example, upgrade specific pneumatic components with smart features or adopt hybrid electric-pneumatic systems. Doing so will allow you to gradually transition to fully digitized production lines without overwhelming capital requirements.

Learn More in Our Webinar

Ready to transform your operations? Watch our webinar for proven strategies on how to improve operations, increase equipment reliability and lower costs: Reduce Downtime and Costs in Your Manufacturing Facility | Festo US.