Build Sound Process Instrumentation and Control Skills

Deficiencies in technical skills are costly and dangerous. Individual training sessions using dedicated equipment allow process workers to hone their practical expertise in a safe environment without interfering with live operations. However, the pedagogical value of the training equipment should not compromise on industry realism, which is essential for smooth and rapid application in the workplace.

A Custom Process Plant for Training Purposes

That is the idea behind our industrial instrumentation and process control learning system. It introduces learners—students or industry professionals—to a wide range of industrial processes and control strategies, as well as to the instruments and control devices used for measuring, controlling and troubleshooting pressure, flow, level, temperature, pH and conductivity.

Its modular structure, choice of technologies and range of components allow the replication of real-life, custom process loops. Several system configurations are available for general or industry-specific process technology training, such as in the oil and gas, water and wastewater, and food and beverage industries, among others.

Many skills can be developed with this system:

- Instruments and principles of operation.

- Installation, calibration and maintenance procedures.

- Integration with control systems (PLCs, DCS, SCADA systems, etc.).

- Safety procedures and alarm management.

- Integration of emerging IIoT technologies.

- And more.

Discover the cornerstone process technology training system used in the school laboratories and training rooms of hundreds of industrial companies:

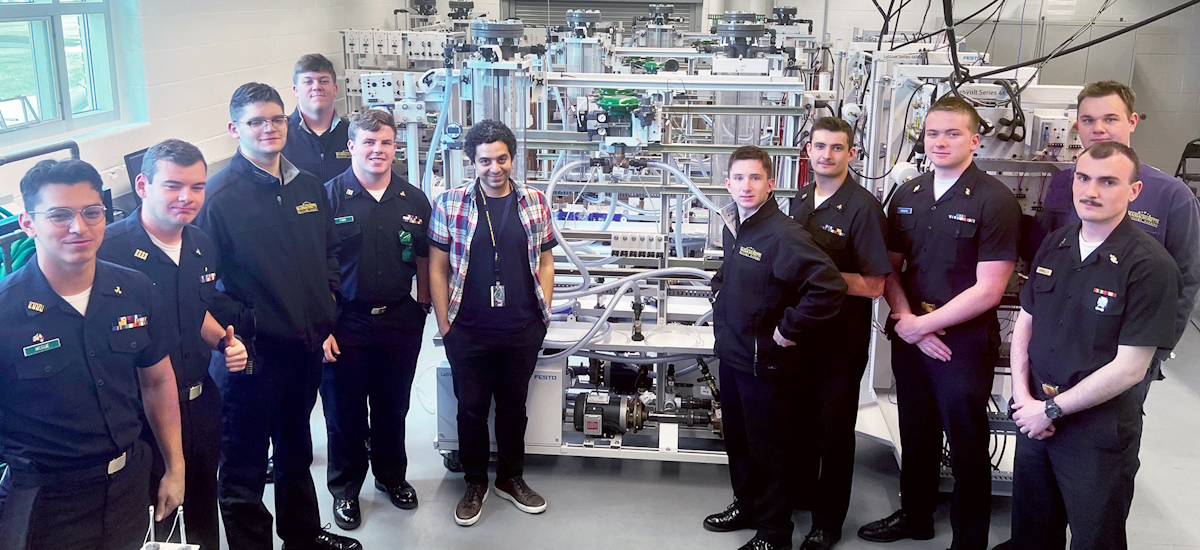

A Logical Choice for Training Future Life Science Workers

This system, along with its accompanying curriculum, was recently selected by the Massachusetts Maritime Academy to prepare cadets for careers in the maritime and growing life-science industries in the Boston area. Their new Instrumentation, Operation and Controls engineering laboratory provides students with more effective hands-on training and equips them with the practical skills needed to work successfully in plant and facility management. Click here to read the full story.

Get in touch with a Festo Didactic specialist to discuss your requirements and start configuring your training system!