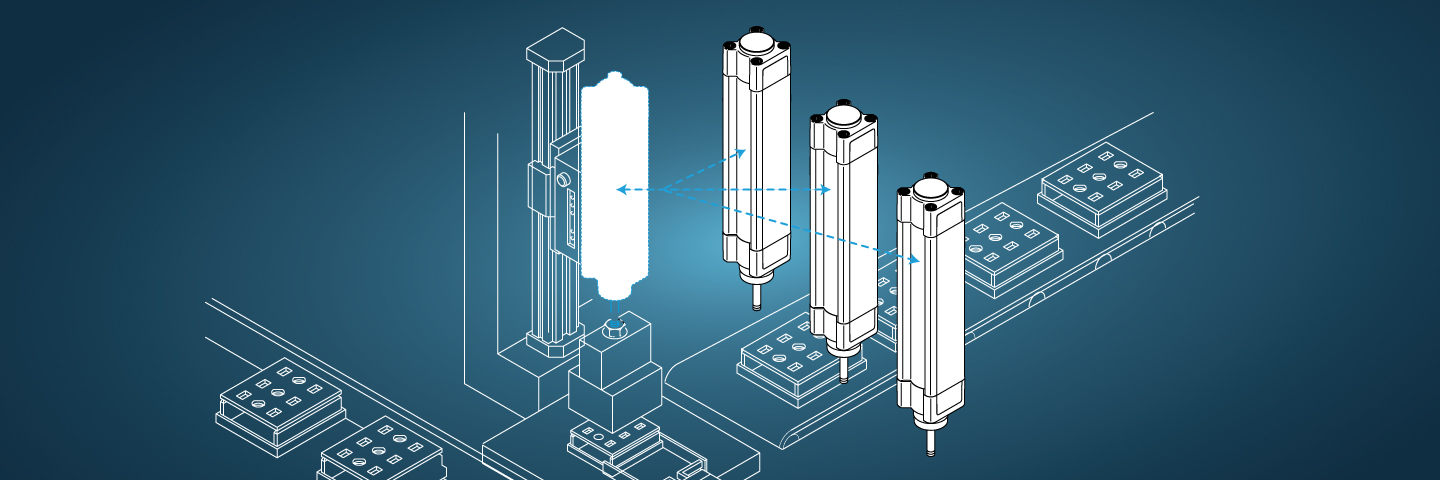

Discover the Benefits of Interchangeable Pneumatic Cylinders in Our White Paper

The standardization of pneumatic cylinders to ISO and NFPA specifications has transformed how machine builders and end-users approach pneumatic actuation systems. These brand-agnostic standards ensure that cylinders remain dimensionally compatible across manufacturers, providing operational continuity that extends decades into the future.

Our latest white paper explores the technical and operational advantages of implementing interchangeable pneumatic cylinders in your industrial application. What follows is a quick overview of what you’ll learn.

An Overview of ISO and NFPA Interchangeability

ISO 15552:2018 cylinders represent one of the most widely adopted standards in industrial pneumatics, specifying critical parameters including bore sizes (32 to 320 millimeters), port threads, mounting interfaces, recommended stroke lengths and available accessories. The standard also defines mounting options, such as trunnion mount configurations, and accessories like clevis brackets.

Similarly, NFPA cylinders serve mostly North American markets where applications require inch ports and threads, while ISO metric standards cover global markets. Key ISO standards include:

- ISO 6432: Round pneumatic cylinders (always round body type).

- ISO 15552: Profile and tie-rod standard cylinders.

- ISO 21287: Compact cylinders.

The backward compatibility contained in these standards ensures long-term viability. For example, ISO 15552 superseded ISO 6431, yet cylinders built to ISO 15552 remain fully compatible with ISO 6431 installations.

The Operational Benefits of Interchangeable Cylinders

Interchangeable pneumatic cylinders deliver several advantages, including:

- Inventory optimization: Brand-agnostic standardization reduces the need for large inventories of replacement cylinders, simplifying inventory control and reducing procurement costs.

- Maintenance efficiency: Standardized interfaces, dimensions and specifications enable straightforward integration into existing equipment without modification requirements.

- Customization within standards: Despite dimensional standardization, manufacturers can customize features while maintaining control dimensions and connections. For instance, you can configure ADN (ISO 21287) compact, double-acting cylinders for high heat applications, enhanced corrosion resistance and explosion protection for electric vehicle (EV) battery production environments.

- Enhanced durability: Standardized cylinders incorporate advanced materials and design features. NFPA cylinders feature high-strength aluminum alloy tubes with hard (60 Rc) coated inner diameters, aluminum alloy pistons with graphite-filled PTFE wear bands and Buna-N Nitrile seals as standard components.

Important Technical Specifications to Consider

Modern interchangeable cylinders combine rugged construction with versatility across a wide range of operating conditions. Critical selection parameters include:

- Tube material selection: Examples include aluminum alloy for standard industrial applications, steel construction for heavy-duty requirements or corrosion-resistant stainless steel for food and hygienic environments.

- Mounting configurations — e.g., multiple bolt patterns and mounting styles.

- Performance optimization: Features include special rod lengths, variable end position cushioning, alternative seal materials and application-specific customizations.

Standards Versus “Cold Spec” Considerations

Understanding the difference between true interchange cylinders and “cold spec” products is critical for engineering decisions. Interchange cylinders conform to NFPA or ISO standards, ensuring guaranteed dimensional compatibility across multiple manufacturers.

Cold spec products, while achieving de facto standard status through widespread use, may vary slightly between brands, introducing potential uncertainty during replacement or upgrade scenarios.

Implementation Strategy and Selection Criteria

Effective implementation of interchangeable pneumatic cylinders requires systematic evaluation of application-specific performance requirements, environmental conditions and integration constraints. Key factors include cylinder type, actuation method, bore size requirements, pressure and temperature specifications, and mounting interface compatibility.

Ready to learn more? Learn how to optimize your pneumatic systems through standardization in our white paper: Discover the benefits of interchangeable cylinders | Festo US.