Is Your Cylinder Replacement Strategy Setting You Up for Failure?

When a pneumatic cylinder fails, every minute costs you — lost output, delayed projects and frustrated teams waiting on parts. One small failure can trigger a domino effect across your production line.

But here’s the real question: Can you replace that cylinder quickly enough to avoid production losses?

If the answer is no — or “I’m not sure” — the root issue may be your cylinder specification. Proprietary or non-standard models may seem fine on paper, but when downtime hits, they can become a bottleneck that halts your entire operation.

Let’s look at how standardization protects you before failure strikes.

Standardization as Risk Mitigation

International Organization for Standardization (ISO) and National Fluid Power Association (NFPA) cylinder standards are brand-agnostic, defining bore sizes, port threads, mounting interfaces and stroke lengths. For example, ISO 15552:2018 profile cylinders specify bore sizes from 32 to 320 millimeters (mm), with standardized mounting options like trunnion mounts and clevis brackets.

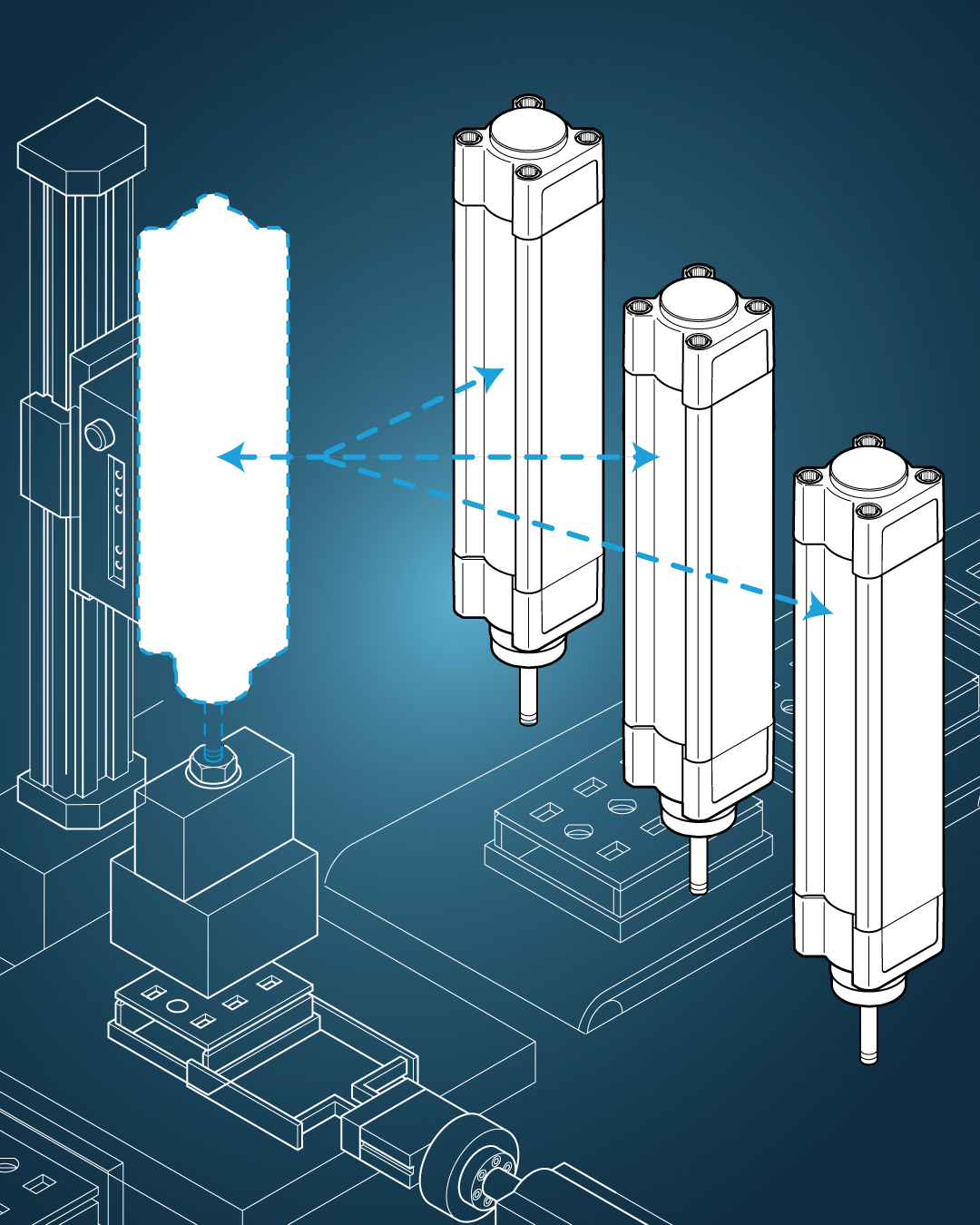

These standards mean any cylinder built to the same standard will fit, regardless of the manufacturer. An ISO 15552 cylinder is a true drop-in replacement for any other ISO 15552 unit. The mounting holes align, the ports match and no modifications are required.

The Hidden Cost of Non-Standard Cylinders

When you specify proprietary or non-standardized cylinders, you create supply chain vulnerability:

- Single-source dependency: If that manufacturer discontinues the model or lacks inventory, you may face extended downtime.

- Expedited shipping costs: Emergency procurement often requires premium freight charges.

- Production losses: Delays easily cascade into missed deliveries and penalty fees.

- Inventory complexity: Multiple proprietary designs require larger spare parts inventories.

Interchangeable cylinders eliminate these risks. Since they’re widely stocked and competitively priced across multiple vendors, replacements are typically available the next day.

Standardization Is Not Just About Emergencies

Beyond fast replacements, standardized cylinders offer long-term operational advantages:

- Backward compatibility: ISO 15552 (introduced in 1999) remains compatible with its predecessor ISO 6431. Equipment designed decades ago can use current-generation cylinders.

- Customization within standards: Cylinders like the ADN (ISO 21287) compact series can be customized for high heat, additional corrosion resistance or explosion protection while maintaining dimensional compatibility.

- Durability and repairability: Standardized cylinders feature high-strength aluminum alloy tubes with hard-coated (60 Rc) inner diameters, corrosion-resistant stainless-steel piston rods and low-wear PUR seals. Many models are designed for disassembly and repair, extending service life.

- Simplified procurement: Brand-agnostic standards mean less inventory overhead and more competitive pricing options.

Cold Spec Versus True Interchange

It’s important to distinguish between “cold spec” cylinders and true interchange products. Cold spec cylinders have achieved de facto standard status through widespread use, but they lack guaranteed dimensional compatibility across manufacturers. Slight variations between brands can introduce uncertainty during replacement. True ISO or NFPA cylinders ensure guaranteed interchangeability across multiple manufacturers — no guesswork or compatibility concerns.

Protect Your Operations Now

The best time to think about cylinder interchangeability is before you face a failure. Whether you’re designing new equipment or reviewing maintenance strategy, standardized cylinders protect you against unexpected downtime.

Download our white paper to explore ISO and NFPA standards and discover how standardized cylinders safeguard your operations. You can also use our online pneumatic sizing and pneumatic simulation tools to select the right interchangeable cylinder for your application.