Assessing and Reducing Machine Risk in Pneumatic and Electric Components

In a new series of blog posts, we’re taking a deep dive into functional safety. Functional safety, which is part of the overall safety of a piece of equipment, reduces the risk of simple and complex systems so that they function safely even in the event of a malfunction. The goal is to prevent harm or damage to personnel, machines and the environment.

This first blog post, which serves as an introduction to this extensive topic, covers the importance of performing risk assessments. It will also explore ways to implement safety functions and sub-functions in pneumatic and electrical systems.

Performing Risk Assessments

A well-proven method for determining machine safety requirements is carrying out a risk assessment. These assessments stipulate protective measures according to ISO 12100, which outlines how to achieve safe machine design. They also enable the implementation of functional safety measures according to ISO 13849, the safety standard that applies to the parts of machine control systems responsible for safety functions.

The risk analysis process involves compiling all required information, identifying the basic hazards and then estimating the risk potential. Then, on the basis of risk estimation, decisions must be made on whether or not protective measures are required for each hazard.

Overall Safety Functions for Pneumatic and Electric Components

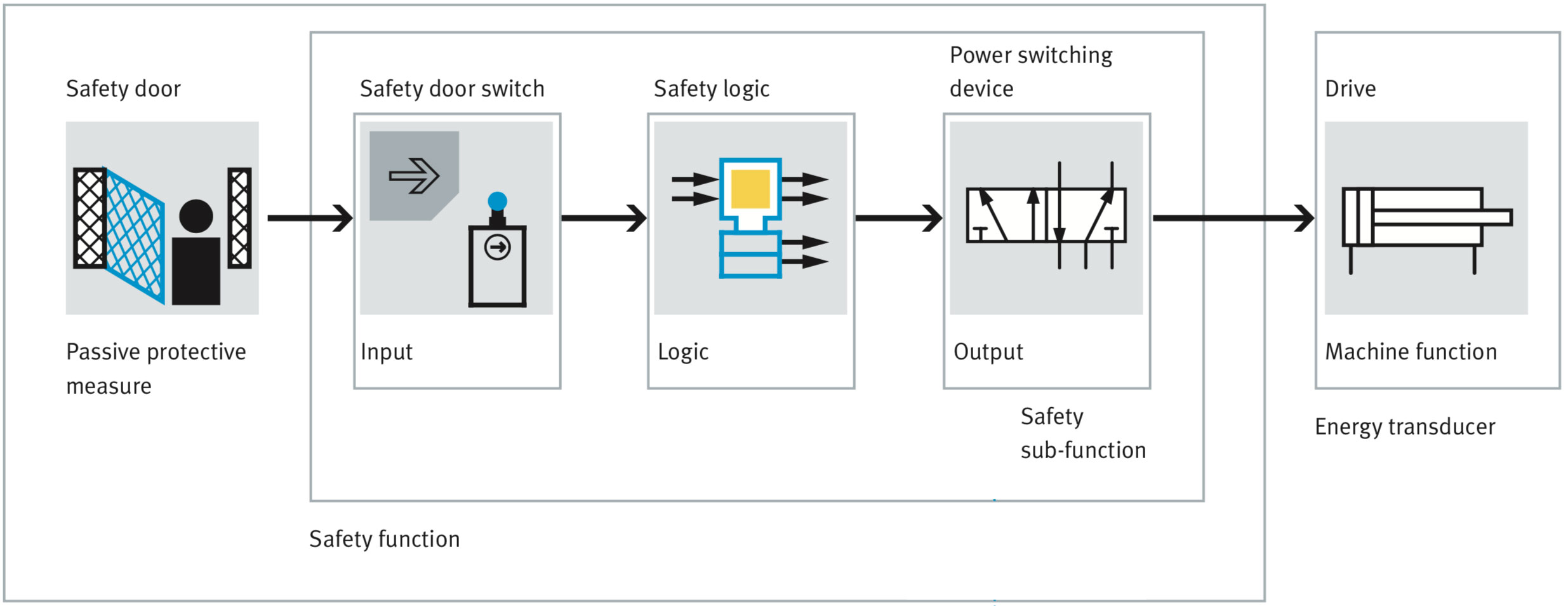

The overall safety function is a protective measure for risk reduction that involves reaching or maintaining a safe machine state. One example is the separation of the operator from the hazard zone. To grant the operator access, the hazardous drive movement is stopped, and the drive is maintained. In this case, the overall safety function consists of a passive protective measure, the sensor (input), the logic (safety relay unit) and the valve combination (output).

Safety sub-functions, which are part of the overall safety function, are performed by a component or group of components in the safety function. A common example is the disconnection of a power switching device—such as a valve or motor controller—from the power supply.

Here are some examples of safety sub-functions in pneumatic and electric drive technology:

Safe Torque Off (STO). This function separates the power supply to the pneumatic drive, exhausting the drive’s chambers and preventing the generation of a dangerous force. In electric systems, the STO function prevents force-generating energy in the electric drive and also unexpected drive startup.

Safe Stop 1 (SS1). This function reduces or blocks the volumetric flow rates in and out of the pneumatic drive’s two chambers, slowing down the drive’s movement and bringing the drive to a stop. If the system reaches a standstill according to the defined tolerance window, then the SS1 function reduces the pressure in the chambers, preventing any dangerous forces. In electric systems, the SS1 function similarly brings the electric drive to a standstill within specific limits.

Safe Operating Stop (SOS). This function prevents pneumatic drives from deviating from the stopping position by more than a specific amount. It also maintains the compressed air supply, enabling the drive to withstand the effect of external forces—for example, variable load—without any further measures. In electric systems, the SOS function supplies energy to the electric drive, enabling it to withstand external forces.

Learn More About Functional Safety With Festo

Engineering for functional safety is one of the most important requirements in factory automation and process industry applications. At Festo, we offer products and solutions that enable you to implement functionally safe, cost-effective engineering as easily as possible. To learn more, please download our functional safety guide.