How to Choose the Right Robot for the Job

Robots come in more designs, sizes and configurations than ever. They can do simple or complex tasks and move payloads ranging from tiny computer chips to large locomotive wheel sets. You can also integrate robots into virtually any manufacturing environment, including food zones, cleanrooms and warehouses.

Given all these options, it’s important to know which type of robot best fits your needs—whether articulated, cartesian, SCARA or delta.

Move small to large payloads with articulated robots. Six- and seven-axis articulated robots are flexible and easy to program, thanks to user-friendly teach pendants. On the hardware side, these robots can be small or large—and can even handle loads weighing over a ton. They also have substantial reach: over three meters depending on your model. With their range of sizes, articulated robots suit a variety of applications involved in the transportation of goods and materials.

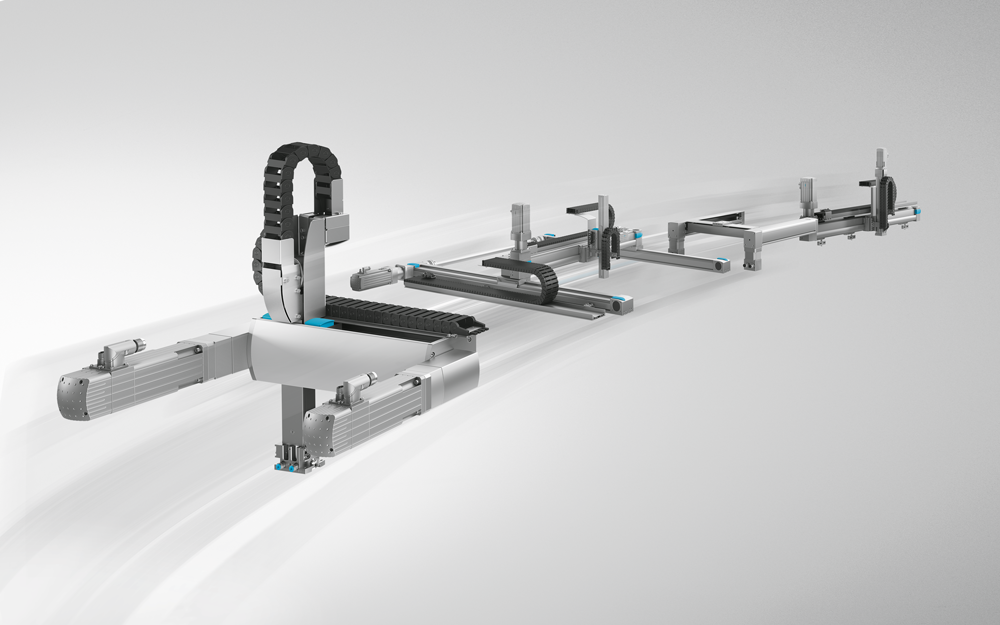

Save space and cost with cartesian robots. One of the lower-cost alternatives is the cartesian robot, which consists of an assembly of linear and rotary actuators. Like articulated models, cartesian robots are easy to install and maintain. They’re also easy to customize in terms of stroke, size and linear axis design. For example, toothed belt actuators enable high velocities while ball screw actuators tend to be more precise and have higher feed forces. Another advantage of this robot type is excellent space economy.

Enable small parts handling with SCARA robots. SCARA (Selective Compliance Articulated Robot Arm) robots were designed and optimized for light applications. A streamlined version of articulated robots, their simplicity and small size make them easy to integrate on assembly lines. They can also achieve impressive cycle times with high accuracy. SCARA robots are adept at functions like inserting components in tight spaces, making them a cost-effective choice in a lot of pick-and-place and parts handling applications.

Perform tasks quickly with delta robots. With pick rates up to 300/min, delta robots are renowned for their speed. Thanks to their design, you can mount them above work zones, saving valuable space. Delta robots are often paired with vision systems to perform complex pick-and-place and sorting tasks. And just like the articulated and SCARA robot, the delta robot comes with a teach pendant for easy programming.

To learn more about which robot type best fits your application, check out our white paper.