Versatile Automation Components for Battery Manufacturing and Assembly

Electric vehicles (EV) are on the rise — and they’re setting a trend when it comes to batteries. To help you ramp up your battery production efforts and meet increasing market needs, you need the right automation components and systems that can support the entire battery manufacturing process, from producing the cells to the final pack assembly.

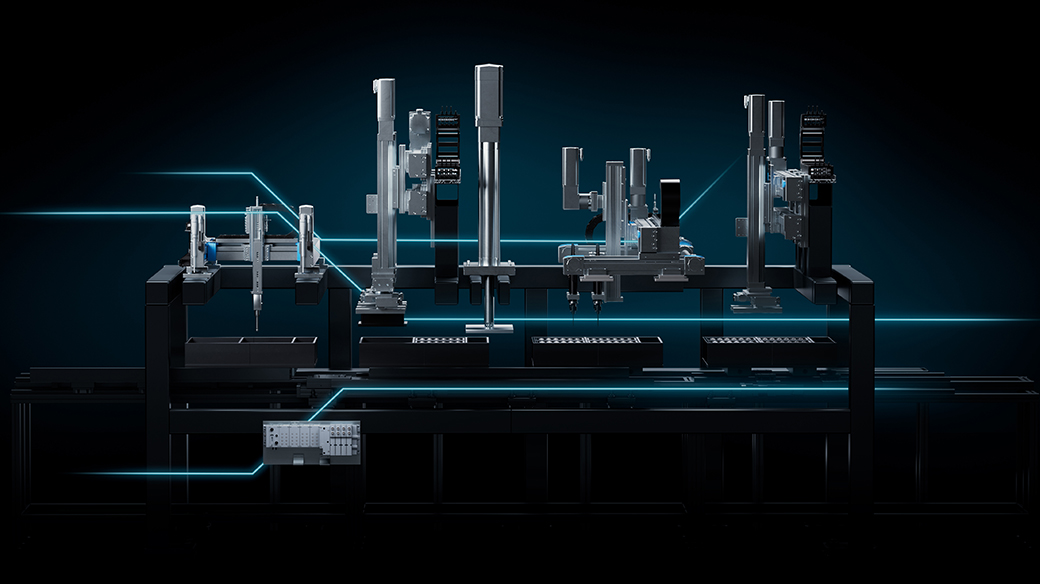

At Festo, we’ve got you covered. A global leader in industrial automation, we have an extensive product line to support both battery manufacturing and the assembly of battery modules and packs. Our products, such as our gantries, valves, cylinders and actuators, as well as our engineering tools, can make your processes more reliable, productive and efficient.

Clean, Reliable Products for Battery Cell Production

When it comes to battery production, achieving high throughput and repeatability are just as important as implementing cost-effective automation solutions. These needs apply to many different process steps — including conveying, feeding and controlling aggressive media.

At the same time, battery production is a highly sensitive process. Contaminants like copper, zinc and electrically conductive or non-conductive particles can reduce the quality of the batteries — and even render them unusable.

To avoid these issues, we offer copper- and zinc-free components, as well as products that are safe for cleanroom environments. For example, components from over 80 product ranges, including Festo cylinders, valves, grippers, compressed air systems, sensors and fittings, all meet ISO Class 7 specifications for cleanrooms. Most are suitable for Classes 6 and 5, and some are even suitable for Class 4.

We also offer many products that meet the stringent requirements for dry rooms, which have a pressure dew point of -50°C — sometimes even -80°C — for lithium-ion cell production. Dry rooms inhibit the hydrophilic properties of many electrolytes, preventing the risk of harmful hydrofluoric acid from forming via reactions with humidity in the ambient air.

Festo products are suitable for environments with dew points of -80°C and even lower, and none of our approximately 60 different greases contain water as part of the lubricant’s formulation.

Products and Engineering Tools To Support Battery Cell Handling

As the EV market ramps up, demand is increasing for battery packs, modules and cells. To keep pace, it’s important to automate the assembly and pick-and-place processes for these components using reliable, versatile automation technologies.

For example, to degas and weld battery cells, you can use our handling systems to load the battery cells onto the workpiece carriers, and then unload the cells afterwards. We also offer electric handling systems, consisting of axis kinematics, motors and servo drives, to support high-speed stacking processes during the production of pouch cells.

Another example involves precise automated handling solutions for EV battery pack assembly. In addition to the electric motor, the heart of the electric powertrain lies in the battery pack. Once the battery cells have been assembled into modules, they must be inserted into the final pack — an operation that relies on automation for safety and precision. While it is common practice to use six-axis robots, gantries offer a more efficient, cost-effective solution. For example, production lines with gantry systems have a footprint that is up to 20 percent smaller.

To help you specify the perfect handling system for your battery assembly process, you can check out the Festo Handling Guide Online, an all-in-one configuration and ordering tool that reduces your engineering and design time for Cartesian systems. Simply specify a single axis, 2D or 3D Cartesian robot, and then insert basic application data like load, cycle time, load voltage and workspace size.

Our intelligent engineering software automatically works out suitable solutions and provides you with downloadable computer-aided design (CAD) models and data sheets. You can then order your robot as disassembled modules or as a fully assembled, pre-parameterized and pre-tested system for your battery handling application.

Visit Festo at the Battery Show

To learn more about our solutions for battery manufacturing and assembly, visit us at the Battery Show, where we’ll have some of our handling systems on display at Booth #2413. The show takes place September 13-15 at the Suburban Collection in Novi, Michigan, so save the date!