Daniella Gonzalez Earned Her Spot on the Team

Daniella Gonzalez, North American Product Manager for Valves and Valve Terminals, has a passion for things mechanical. “I’ve been interested in how things work my entire life,” Gonzalez said. “As a child, I was always taking things apart and sometimes putting them together again.”

Gonzalez was born and grew up in Mexico. She completed her education in the U.S. and was the sole female mechanical engineering graduate in her college class. “Science, Technology, Engineering, and Math (STEM) offers incredible opportunities for women of all ages,” she observed.

“I’ve been with Festo for 10 years and see many more women in the sciences, engineering, and manufacturing than when I started. To be successful in areas where men are in the majority, I believe women succeed best when they possess a firm determination and sense that they are going to achieve their aims – in other words, believe in yourself. By achieving your goal, you prove that you’ve earned your spot on the team – you’re here just like everybody else.”

As a Festo product manager, Gonzalez handles every facet of product support for valves and valve terminals in North America – strategic planning, ensuring adequate supply, promotion, technical support, and training. “I love the training aspect of this job,” she said. “I’m a people person and it gives me a chance to get to know people and build relationships.”

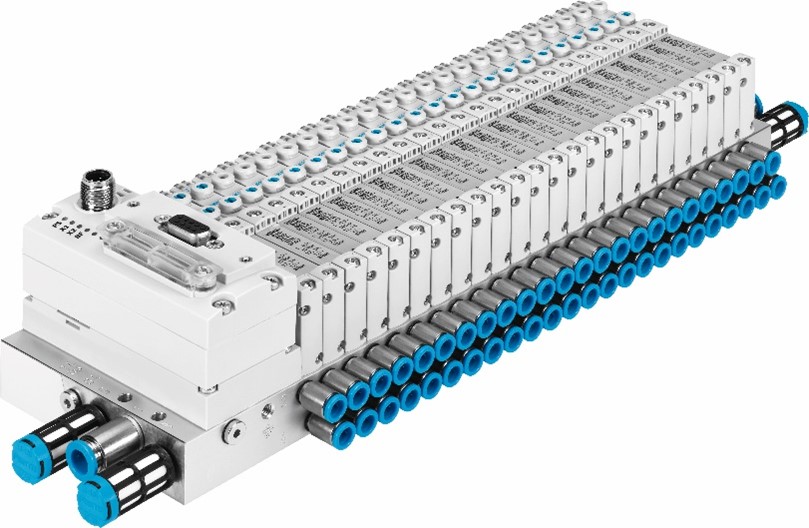

Gonzalez currently promotes the innovative VTUG family of valve terminals. “VTUG recently earned its certificates for UL Class 1 Division 2 explosion proof environments, in conjunction with fieldbus protocols,” Gonzalez said. “It already had its ATEX and UL ordinary location certificates. The extension into hazardous environments with fieldbus protocols is unique to Festo and shows the VTUG family’s exceptional range of applications.”

Original equipment manufacturers (OEMs) can mount the VTUG in a control panel or on their machine for maximum flexibility. It is simple to connect to power, communication, and pneumatic tubing. The VTUG’s sleek design enhances the appearance of the machine or control cabinet. The VTUG has a top-end 48-solenoid capacity in the same space required of 24 valves by using dual valves, which means the manifold requires less space but provides greater capabilities than other manufacturers’ solutions. This is a plus for OEMs answering their customers’ demand for smaller footprint, yet higher performing machines.

The VTUG’s variable flow rates are key to its flexibility, with flow ranges from 300 liters/minute up to 1200 liters/minute. For its size, the VTUG’s flow rate is 30 to 40 percent higher than comparable manifolds. These units are compatible with all leading control platform communications protocols, including EtherNet/IP, PROFINET, and EtherCAT.

Gonzalez said that OEMs standardizing on the VTUG valve terminal family of products enjoy many advantages, including faster design, simplified procurement, and lower inventory requirements. As a core Festo valve terminal family, VTUG and its accessories are stocked globally for speedy shipping for new machines and for fast, assured field replacement.

“I love working at Festo,” Gonzalez said. “It feels like being part of a large family. And our products are so innovative and well-engineered that it makes me proud to know I’m helping customers succeed. As a product manager, I provide Festo customers with the low risk, cost-effective, outstanding solutions they require.”